Don't just focus on the appearance of doors and windows, these hardcore parameters are the touchstone for high-end living

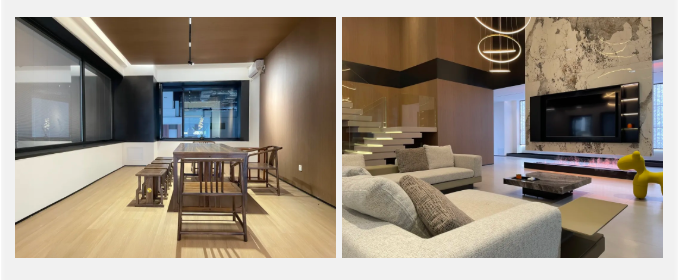

In the high-end home consumption market, many people tend to fall into the misconception of "appearance first" when choosing doors and windows, focusing too much on surface colors and textures, while ignoring the core parameters that determine the living experience.

The selection and comprehensive design of materials such as profiles, glass, and hardware are important criteria for determining the performance of doors and windows, and are also key indicators for dividing the quality level of living. Passive always takes strict parameter standards as the cornerstone, building an ideal living barrier that combines aesthetics and performance for users from the source.

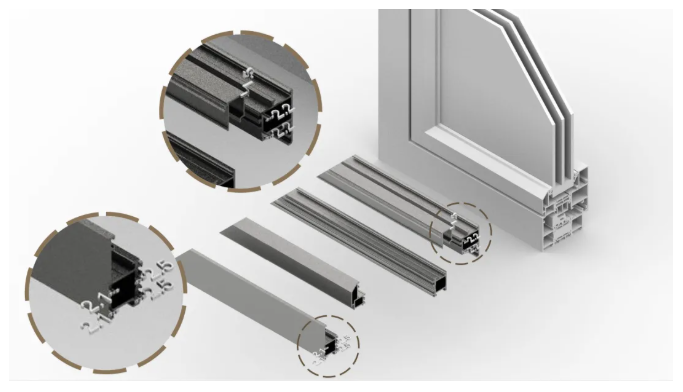

High standard profiles build a strong foundation for safety and durability

As the "skeleton" of doors and windows, profiles directly affect the stability, wind resistance, and service life of products. The material selection and wall thickness parameters of profiles are important indicators for measuring their performance.

Some doors and windows on the market use ordinary aluminum alloy profiles to reduce costs, which not only have weak deformation resistance, but are also prone to problems such as gaps and looseness after long-term use.

Passive adheres to high standards and strict requirements, using EN AW 6060-T66 ultra high precision profiles. The accuracy is 40% higher than ordinary aluminum profiles, and the strength is 45% higher than ordinary aluminum profiles. The cantilever thickness of the profile reaches 2.0mm, far exceeding the basic standard.

Such data performance means that doors and windows can have stronger load-bearing capacity and wind pressure resistance. Even in the face of extreme weather such as typhoon and rainstorm, they can also maintain the structural stability of doors and windows and eliminate hidden dangers such as deformation and water seepage. At the same time, in daily use, it can effectively resist the impact force of opening and closing, extend the service life of doors and windows, and provide users with long-term stable quality assurance.

All products of Passive are made of broken bridge aluminum profiles and effectively block heat conduction through multi cavity design and the use of insulation strips. This reduces the entry of outdoor heat in summer and prevents indoor heat loss in winter, making home temperatures more stable. The energy-saving effect far exceeds that of ordinary aluminum alloy doors and windows.

High performance glass creates a comfortable and livable environment

As the "eyes" of doors and windows, glass's parameters directly affect the indoor lighting, insulation, and sound insulation effects. Ultra white glass, Low-E coating, argon filling of insulating glass, 4SG flexible warm edge, etc. have become key breakthroughs in improving the comprehensive performance of glass.

The iron content in ultra white glass raw materials is only 10% or even lower than that of ordinary glass, and the visual effect is almost transparent. In addition, through special processing, ultra white glass can significantly reduce the reflection and scattering of light, and improve the transmittance of light. The transmittance of ordinary glass (6mm) is generally around 85%, while the transmittance of ultra white glass with the same thickness can reach over 91%.

The surface emissivity of ordinary glass is as high as 0.84, while the surface emissivity of commonly used Low-E glass coating surfaces is less than 0.15. Low-E glass's low absorption (low emissivity) of solar radiation reduces indoor secondary heat transfer. Meanwhile, compared to ordinary glass, Low-E glass has a lower heat transfer coefficient K value and stronger resistance to temperature difference heat transfer, effectively achieving cooling in summer and insulation in winter.

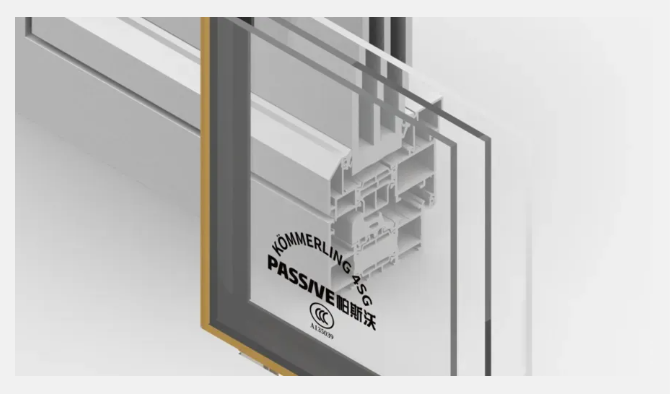

As an inert gas, argon has low activity, which can effectively prevent oxidation of Low-E glass coating layer and extend the service life of coated glass. At the same time, by reducing the heat conduction of the hollow layer gas and lowering the heat transfer coefficient K value, it can achieve better insulation and heat preservation. Passive uses high-quality insulated glass, which can be filled with argon gas inside. The argon gas content meets or even exceeds relevant standards. According to authoritative laboratory test results, Passive's glass can achieve long-term sealing for 50 years through argon gas circulation testing.

Behind the high durability of hollow glass gas seals, the continuous development of hollow glass sealing technology is indispensable. The thermal conductivity of 4SG thermoplastic reactive spacer sealant is only 0.2W/(m · K), which can significantly reduce the heat conduction at the edge of the glass, thereby reducing the heat loss at the edge of the glass. At the same time, it can effectively reduce the probability of condensation on door and window frames and glass edges, and inhibit the production of mold. At the same time, the 4SG system can achieve true chemical bonding with glass and secondary sealant, forming a structural seal, thereby ensuring that argon gas does not leak and guaranteeing the long-term life of Low-E membranes and insulating glass.

Passive collaborates with glass deep processing enterprises authorized by Kemelin, using genuine Kemelin reactive spacer sealant for flexible warm edges.

High quality hardware ensures a smooth and silky experience

If profiles and glass are the "bones" of doors and windows, then hardware accessories are the "joints" of doors and windows. The quality of hardware components such as hinges, handles, and locks directly determines the smoothness, sealing, and anti-theft safety of door and window switches.

Some low-end doors and windows on the market use inferior hardware, which can cause problems such as rusted hinges, loose handles, and malfunctioning locks after one or two years of use. This not only affects the user experience but also poses safety hazards. Passive always adheres to the principle of "details win", and all hardware accessories are selected from well-known big brands.

The surface of the handle has undergone multiple layers of anti-corrosion treatment, and it can still maintain a smooth and new appearance even after long-term use, with a service life far exceeding the industry average; The hinge is made of high hardness alloy material and precision machining technology, which can withstand tens of thousands of switch tests; The lock adopts a multi-point locking structure, combined with anti pry design, which can effectively resist external damage.

In addition, the selected hardware and profiles have a higher degree of compatibility, with smooth and seamless opening and closing. When closing doors and windows, they can achieve a tight fit, effectively preventing rainwater leakage and air infiltration, further improving the insulation and sound insulation effects of doors and windows.

The quality of doors and windows is never just about "seeing", but also about being able to withstand "testing". Behind every core parameter of profile wall thickness, glass configuration, hardware brand, lies the ultimate pursuit of living quality.

Based on strict performance standards, Passive provides support for high-end living quality, making every door and window switch a beautiful interpretation of comfortable living.